Electromagnetic Detection (ET)

Principle :

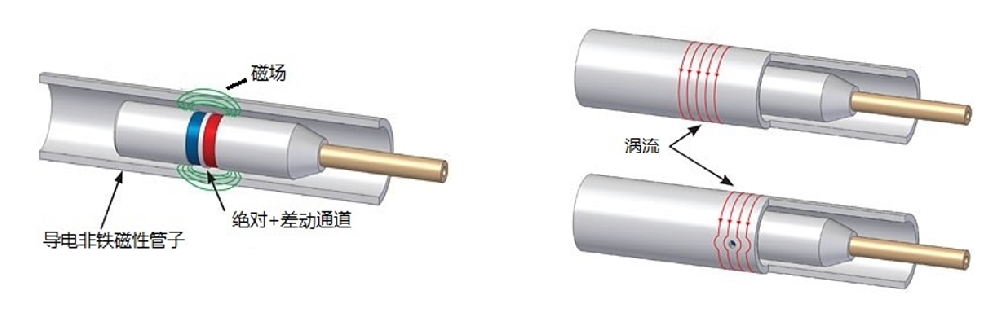

Place the coil with alternating current on the metal plate to be tested or cover it outside the metal tube to be tested (see picture). At this time, an alternating magnetic field will be generated in and near the coil, so that a vortex-shaped induced alternating current, called eddy current, will be generated in the test piece. The distribution and size of the eddy current are not only related to the shape and size of the coil, the size and frequency of the alternating current, etc., but also depend on the electrical conductivity, magnetic permeability, shape and size of the specimen, the distance from the coil, and whether there are cracks on the surface. defects, etc. Therefore, under the condition of keeping other factors relatively unchanged, a detection coil is used to measure the magnetic field change caused by the eddy current, and the size and phase change of the eddy current in the test piece can be inferred, and then the relevant conductivity, defects, material condition and other physical quantities can be obtained. (such as shape, size, etc.) changes or the existence of defects and other information. However, since eddy current is an alternating current and has a skin effect, the detected information can only reflect the situation at or near the surface of the specimen.

Application : According to the shape of the test piece and the purpose of detection, different forms of coils can be used, usually there are three types of through-type, probe-type and insertion-type coils. The pass-through coil is used to detect pipes, bars and wires. Its inner diameter is slightly larger than the object to be inspected. When used, the object to be inspected passes through the coil at a certain speed, and defects such as cracks, inclusions, and pits can be found. The probe coil is suitable for local detection of the test piece. When applied, the coil is placed on a metal plate, tube or other part to check for fatigue cracks on the inner barrel of aircraft landing struts and turbine engine blades. The plug-in coil, also known as the internal probe, is placed in the hole of the pipe or part for inner wall detection, and can be used to check the corrosion degree of the inner wall of various pipes. In order to improve the detection sensitivity, most probe-type and insertion-type coils are equipped with magnetic cores. The eddy current method is mainly used for the rapid detection of metal tubes, rods and wires on the production line and the flaw detection of large quantities of parts such as bearing steel balls, valves, etc. Material sorting and hardness measurement, and can also be used to measure the thickness of coatings and coatings.

Features :

1. For the detection of metal pipes, rods and wires, no contact or coupling medium is required. Therefore, the detection speed is high, and it is easy to realize automatic detection, which is especially suitable for online general inspection. 2. The detection sensitivity of surface defects is very high, and it has a good linear indication within a certain range. It can evaluate defects of different sizes, so it can be used for quality management and control. 3. There are many factors that affect the eddy current, such as cracks, materials, size, shape, electrical conductivity and magnetic permeability. Using a specific circuit for processing, one factor can be screened out and other factors are suppressed, so that it is possible to effectively detect the above-mentioned individual influencing factors. 4. Since there is no need to contact the workpiece and no coupling medium during inspection, the inspection at high temperature can be carried out. Since the probe can be extended into the remote operation, it can detect the narrow area of the workpiece and the wall of the deep hole (including the wall of the pipe). 5. Due to the use of electrical signal display, it can be stored, reproduced and compared and processed. 6. The object of eddy current testing must be conductive materials, and due to electromagnetic induction, it is only suitable for detecting metal surface defects, not for detecting deep internal defects of metal materials.

Our company currently has a professional team of senior engineers and engineers. The main inspectors are composed of a team of engineers who have been engaged in non-destructive testing for many years, with strong technical ability and rich experience. All inspectors have professional inspection qualifications, including non-destructive testing (ASNT/ISO9712 II/III and national special equipment non-destructive testing qualification II/III), American Association for Materials Performance and Protection (AMPP-Coatings Inspector/Senior Coatings Inspector), welding inspection (CWI, SCWI), International Welding Engineer IWE, API 653, API 510, API 570, API 571, API Quality Engineer, Senior Mechanical Engineer, etc.

The following inspection services can be provided for enterprises:

Penetrant Testing (PT), Magnetic Particle Testing (MT), Ultrasonic Testing (UT), Phased Array (PAUT), Time-of-Flight Diffraction (TOFD), Radiographic Testing (RT), Visual Testing (VT), Eddy Current Testing (ECT), Leak Testing (LT), Magnetic Leakage Detection (MFL), Acoustic Emission Detection (AE), Digital Imaging (DR), Real-time Imaging Detection (CR), Alternating Current Field Measurement (ACFM), etc.