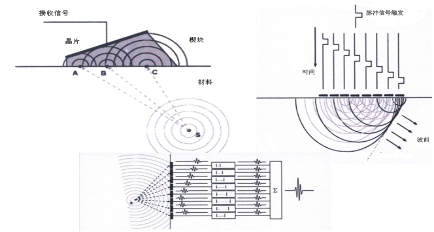

Principle : The phased array transducer is composed of a plurality of independent and independently controllable piezoelectric wafers. By controlling the physical inclination and electronic delay, the transducer wafers are excited to emit ultrasonic waves according to certain rules and sequences, and each wafer emits ultrasonic waves. Ultrasound is considered to be the same frequency. At a certain point on the sound transmission medium, when each wave front arrives at the same time, a superposition of wave crests will be formed at this point to achieve energy accumulation, so as to more effectively detect the discontinuity of the medium.

Schematic

Detection technology features :

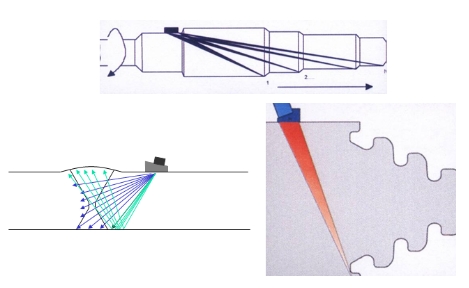

Compared with ordinary ultrasonic testing technology, ordinary ultrasonic can only use one angle of probe detection at a time, and phased array testing technology can electronically control the sound beam angle of the probe to be between -70°~70° or 0~90° (increase the wedge). It can be deflected arbitrarily in the block) to form a fan-shaped scan, or a line-shaped scan at a suitable angle, and the sound beam can be dynamically focused during the scan to increase the sensitivity and measurement accuracy.

Phased array ultrasonic testing technology features

( 1) Smaller probe size, able to detect inaccessible parts; ( 2) Fast detection speed, real-time recording and display of test results; ( 3) Real-time color imaging, including A/B/C/D and S-scan imaging It is easy to identify defects and improve the detection accuracy; ( 4) It has fan scanning and linear scanning, which can achieve 100% beam coverage in the weld area and improve the detection rate; ( 5) It has strong detection flexibility and is suitable for various Inspection of pipe diameter (up to flat plate), wall thickness, and groove-shaped welds, and good at detecting structural parts of various complex shapes ( 6) It is easy to detect defects in various directions and different positions, with high quantitative and positioning accuracy; ( 7 ) ) can be dynamically and deeply focused to improve the defect signal-to-noise ratio and detection sensitivity; ( 8) The detection results are less affected by human factors, and the data is easy to store, manage and recall.

Our company currently has a professional team of senior engineers and engineers. The main inspectors are composed of a team of engineers who have been engaged in non-destructive testing for many years, with strong technical ability and rich experience. All inspectors have professional inspection qualifications, including non-destructive testing (ASNT/ISO9712 II/III and national special equipment non-destructive testing qualification II/III), American Association for Materials Performance and Protection (AMPP-Coatings Inspector/Senior Coatings Inspector), welding inspection (CWI, SCWI), International Welding Engineer IWE, API 653, API 510, API 570, API 571, API Quality Engineer, Senior Mechanical Engineer, etc.

The following inspection services can be provided for enterprises:

Penetrant Testing (PT), Magnetic Particle Testing (MT), Ultrasonic Testing (UT), Phased Array (PAUT), Time-of-Flight Diffraction (TOFD), Radiographic Testing (RT), Visual Testing (VT), Eddy Current Testing (ECT), Leak Testing (LT), Magnetic Leakage Detection (MFL), Acoustic Emission Detection (AE), Digital Imaging (DR), Real-time Imaging Detection (CR), Alternating Current Field Measurement (ACFM), etc.