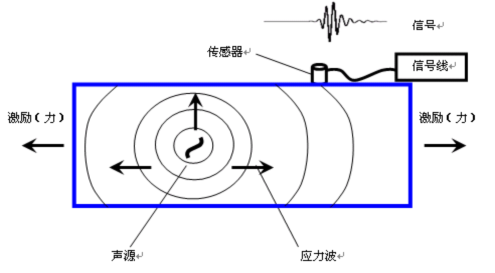

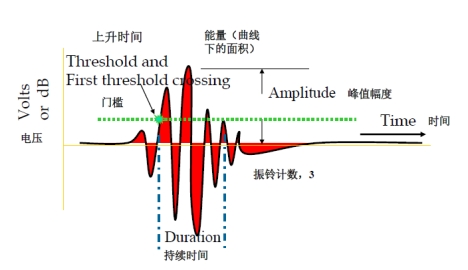

Acoustic Emission ( AE) refers to the transient state caused by the rapid release of elastic energy when an object is subjected to deformation or external force.

A physical phenomenon of stress waves.

The main features of acoustic emission detection technology are as follows:

●Acoustic emission testing technology is a dynamic nondestructive testing technology. This is the fundamental difference between acoustic emission detection and other detection techniques. The sound source energy detected by acoustic emission comes from the active defect of the tested object itself, not provided by non-destructive testing equipment (such as ultrasonic or radiographic testing methods). Therefore, the acoustic emission detection technology has the characteristics of real-time and online, and has a wide application prospect.

The acoustic emission detection method has no special requirements on the geometry of the components, and is suitable for the detection and evaluation of active defects of components with complex shapes.

l Acoustic emission detection technology is an overall detection technology. In a test process, by arranging a small number of fixed sensors in a certain array, the acoustic emission detector can obtain the activity information of the sound source in the detected object during the detection process, and can determine the approximate position of the sound source. It is suitable for online monitoring of industrial processes and early or now damage forecasting.

●Acoustic emission detection method is more sensitive to linear defects, it can detect the activity of these defects under external structural stress, stable defects do not produce acoustic emission signals.

●For the periodic inspection of equipment in use, the acoustic emission inspection method can shorten the downtime of inspection or eliminate the need for production downtime.

It can be seen from the above characteristics that acoustic emission testing is very different from conventional nondestructive testing methods, and can accomplish many tasks that conventional testing cannot.

Our company currently has a professional team of senior engineers and engineers. The main inspectors are composed of a team of engineers who have been engaged in non-destructive testing for many years, with strong technical ability and rich experience. All inspectors have professional inspection qualifications, including non-destructive testing (ASNT/ISO9712 II/III and national special equipment non-destructive testing qualification II/III), American Association for Materials Performance and Protection (AMPP-Coatings Inspector/Senior Coatings Inspector), welding inspection (CWI, SCWI), International Welding Engineer IWE, API 653, API 510, API 570, API 571, API Quality Engineer, Senior Mechanical Engineer, etc.

The following inspection services can be provided for enterprises:

Penetrant Testing (PT), Magnetic Particle Testing (MT), Ultrasonic Testing (UT), Phased Array (PAUT), Time-of-Flight Diffraction (TOFD), Radiographic Testing (RT), Visual Testing (VT), Eddy Current Testing (ECT), Leak Testing (LT), Magnetic Leakage Detection (MFL), Acoustic Emission Detection (AE), Digital Imaging (DR), Real-time Imaging Detection (CR), Alternating Current Field Measurement (ACFM), etc.